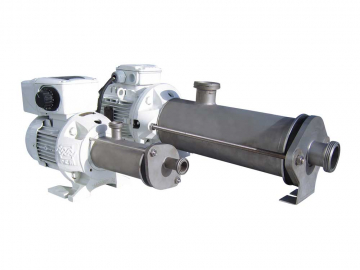

What are food progressing cavity pumps?

Progressing cavity pumps are a type of rotary volumetric pump that consist of a helical rotor, which turns inside a helical stator When the rotor turns into the stator, the honeycomb progresses spirally along the axis of the pump transferring the product from the pump suction to the pump discharge. They are pulsation-free and capable of handling higher pressure (up to 24 bars), making them ideal for jobs in the food sector that require a steady flow of liquid regardless of viscosity.

How does progressing cavity pump work?

What are progressing cavity pumps used for?

PCPs are largely used in food processing industries. Designed according to the strictest hygiene standards, these pumps are appreciated for product respect and steady flow. The PCP technology is ideal for dairy products (milk, eggs, and yogurts). These PDPs are also prevalent in the sector of fruit handling, assist in agricultural food production and are used in the cosmetic industry to produce and maintain high quality products whilst promoting the latest level of hygiene standards.

Progressing cavity pumps have a reputation for their wide capabilities, and with PDP varieties available for food transfer pumps and systems there are many uses for progressing cavity pumps. Food transfer pumps are an integral aid when it comes to handling delicate ingredients and creating expensive recipes with components that can be often difficult to work with. However, when it comes to fluid processing, PCPs are capable of dispersing both fragile and thick liquids, including corrosive substances and liquids that contain solids, without damaging the product.

What are the advantages of PCP?

- Easy to maintain

- Cleanable in place (CIP)

- Low shear pump

- Flow rate is proportional to running speed

- PCPs are reversible to suit your requirements

What are the maximum performances?

- Pressure: up to 24 bars (standard pump)

- Flowrate: from 3l/h to 180 m3/h

- Particle sizes: up to 32 mm