Industrial food mixers

Mix with care: introducing a better way to mix

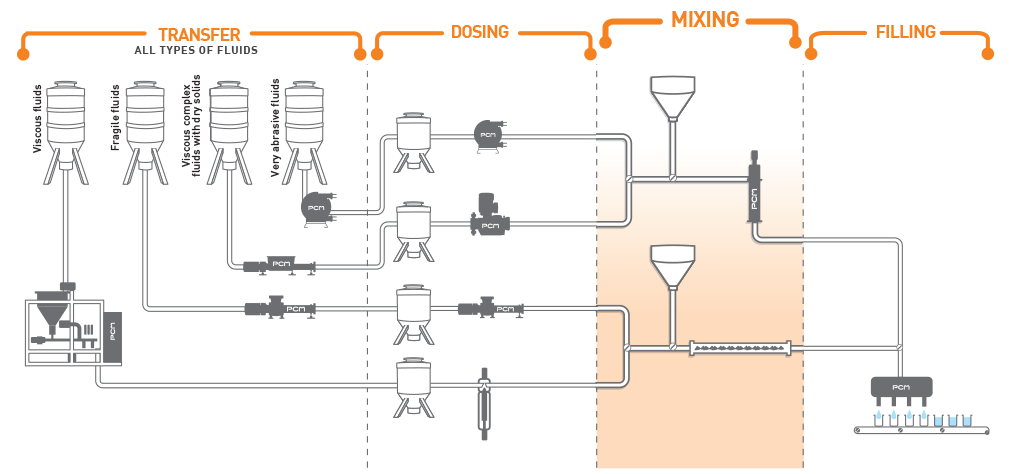

With food grade pumps, PCM gives the opportunity to customers to optimise the overall operating cost through an inline process rather than expensive and space consuming batch solutions.

PCM industrial food mixers give you the freedom to create innovative compositions while protecting costly ingredients. They mix using progressive contact rather than beating, making it possible to blend a wide range of fluids with varying levels of viscosity and solids. Industrial food mixers are a smart solution to mix with care.

Benefits of PCM pumps and systems for mixing applications

Less loss with industrial food mixers

With PCM inline mixers, less product is lost when switching recipes or at the end of a production run. And because they blend using smaller volumes, they are ideal for mixing tasks that require the just-in-time addition of blending time-sensitive ingredients.

More flexibility

When your production requires rapid ingredient change, a PCM inline mixer is the answer. You can switch ingredients in mid-production without having to empty the batch tank first. Our inline mixers can also be fitted with multiple outlets for extremely even distribution through multiple filling nozzles.

Damage-free mixing

PCM inline mixers produce homogenous blends without altering product or ingredient consistency. This eliminates the use of expensive additives to recover texture. Our mixers are also particularly well suited to handling fragile solids, such as fruits, thanks to the gentle non-shearing mixing action.

Cost-efficient cleaning

With a PCM inline mixer there is no tank to scrape at the end of a production run, unlike with batch mixing. And the mixer’s small internal volume makes it easy to clean with minimal quantities of hot water and chemicals, using your standard CIP/SIP processes.