Dosing pumps & liquid dosing systems

Never waste a drop: the perfect dose of accuracy and flexibility.

Inaccuracies and flexibility deficiencies of food processing systems are the main causes linked to high operating costs for most of food production systems.

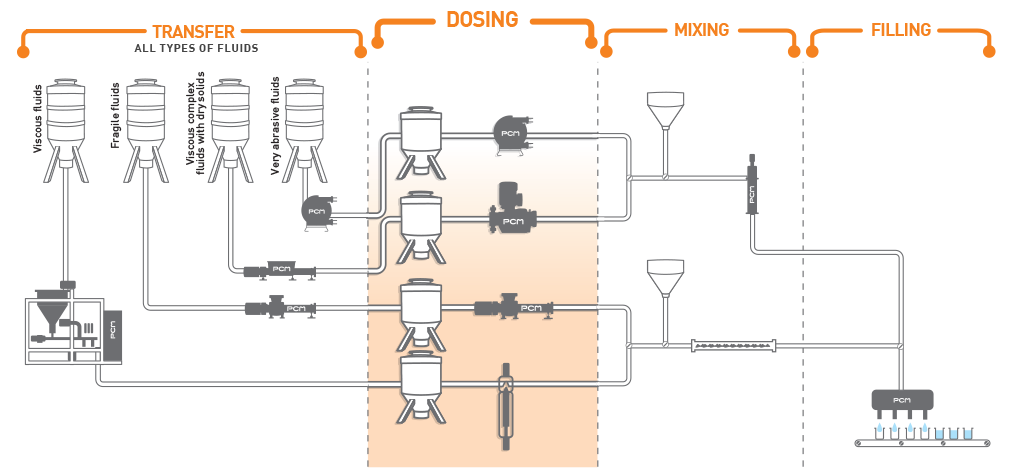

The PCM dosing systems are designed to meet the requirements associated to each metered product, the required accuracy and the implemented operating processes. Each technology that is used provides the best of its advantages regarding accuracy, product losses, texture respect, productivity and cleaning ease.

Benefits of PCM Dosys™ piston dosing pumps

Dosys™ pump technology sits at the heart of all PCM dosing systems. Invented by PCM, it makes it feasible to replace wasteful dosing systems with highly accurate and efficient inline injection.

Accuracy

Dosys™ technology automatically synchronizes dosing volumes with the filling station for optimal performance. It also meters the ingredients with precision, thanks to the servo-driven piston and a patented flow-control valve.

Gentle pumping

Dosys™ pumps handle ingredients with large semi-solids (0 48 mm) without damaging them. Because there is no rotating movement, solids remain suspended in the liquid medium; no emulsion or aeration are created.

Flexibility

Dosys™ pump are designed to handle liquids, semi-solids and viscous products. The dosing volume can be easily adjusted by simply increasing or decreasing the piston movement.

Easy cleaning

Dosys™ pumps can be cleaned in place (CIP/SIP) with no dismantling or the need for complicated bypass systems.

Other technologies associated to dosing applications

PCM Delasco™ peristaltic pumps

PCM Delasco™ peristaltic pumps are ideal for the dosing of highly abrasive and aggresive fluids.

PCM Moineau™ progressing cavity pumps

They allow the continuous dosing of fragile ingredients for applications that may require high flowrates.

PCM Lagoa™ diaphragm dosing pumps

These diaphragm dosing pumps allow metering small doses of low viscous/corrosive products.