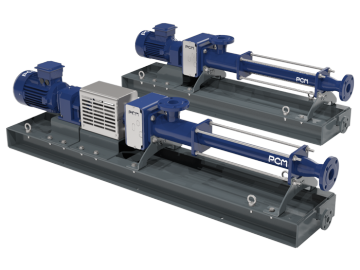

Moineau™ progressing cavity crude oil transfer pumps

Founder of the PCM company in 1932, René Moineau is the inventor of the Progressing cavity pump, also known as « Moineau pump ». PCM provides cost-effective oil pumps integrated within our pumping systems, as well as oilfield services for a range of surface transfer needs, including API 676 compliance.

Progressing cavity pump principle

PCM Moineau™ transfer pumps use patented PCP technology to provide optimal performance for all applications. Our Progressing Cavity Pump comprises a metallic rotor with a helical profile, as well as an elastomeric stator with a double helix profile.

PCM Moineau™ transfer pumps use patented PCP technology to provide optimal performance for all applications. Our Progressing Cavity Pump comprises a metallic rotor with a helical profile, as well as an elastomeric stator with a double helix profile.

When the rotor is assembled within the stator, a series of sealed cavities are formed inside the pump, each of identical size and profile. When the pump is running, the rotor turns, allowing the cavities to move in a spiral path from one end of the pump to the other. This conveys fluid from the inlet to the outlet of the pump.

Rotor

The pump’s rotor is manufactured from high strength steel, and is coated to minimize abrasion from pumped fluids whilst reducing rotor/stator friction. The rotor is machined using a special lathe to achieve a precise diameter. This allows it to work effectively in combination with your chosen stator design, and for your specific application.

Stator

The stator is made from one of a range of elastomers which are formulated to suit a variety of pumped fluids and applications, up to temperatures of 150°C (300°F). The stator’s design is also influenced by mechanical strength, as well as chemical and abrasion resistance.

PCM is proud of its status as one of the few oil pump manufacturers to develop its own elastomers in-house – and we’ve been doing so for over 80 years, giving us unrivalled expertise in the business.