Produced water treatment

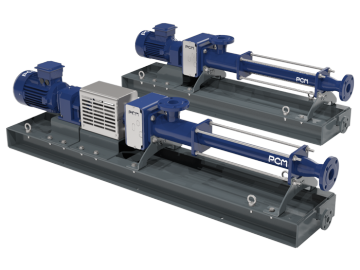

Oil and water mixtures are prone to emulsification during pumping. With the absence of non-return valves and with their unique PCP conveying principle, our PCM surface transfer pumps offer low-shear pumping.

This is ideal for produced water transfer and for maximizing the efficiency of separation systems for on-shore as well as offshore applications. Our high pressure pumps offer a low OPEX solution for onshore water injection applications.

Produced water treatment challenge

Large consumer of water, the oil and gas industry also produces large amounts of water during oil and gas extraction. On average, about 7 to 10 barrels, or 280 to 400 gallons, of water are produced for every barrel of crude oil. To achieve maximum oil recovery, water is often injected into the reservoirs to help improve oil recovery, or into disposal wells. On shore or offshore, produced water must be treated to be recycled for subsurface injection or rejected with regulatory guidelines to permit land applications or discharge and offsite trucking.

Why choose PCM for produced water disposal ?

- Our pumps are available in corrosion resistant alloy materials suited to highly corrosive and hazardous fluids with high salinity or sour oil and water (NACE MR0 175/ISO 15156 certification). High-integrity mechanical sealing ensures zero process leakage for maximum operator safety.

- We offer low shear pumping which ensuresmaximum separator performance by maintaining oil droplet size. This reduces dependency on expensive chemicals (demulsifiers, flocculants and coagulants) and improves overall efficiency of the produced water treatment process.

- From our years of experience in the Oil & Gas Industry, we know that occasionally there are projects with specific challenges that cannot be met using surface transfer pumps in their standard form. This is why we create engineered solutions. In offshore where space is at a premium, PCM engineered long shaft vertical pump solutions combine the benefits of our standard pump with a space saving design. This provides a smaller footprint and reduces the weight of FPSO and platform topsides equipment.

Customer reference

FPSO, offshore West Africa

- Pump: 390THP15

- Fluid: produced water

- Flowrate: 50m3/h (220 USGPM)

- Differential pressure: 8 bar (120 psi)

- NPSHa: 1.0 m

- API 676 compliant