Sludge grinder - PCM Macerator

A simple and reliable shredding solution

PCM Macerator shredders provide a simple and reliable grinding solution for pump preservation, providing effective protection against filasses and bulky particles in wastewater treatment plants and drinking water treatment units.

Proven shredding concept

A tried-and-tested shredding concept that is based on the use of a perforated plate in combination with a rotating cutting head.

Suitable for various water treatment plants

Suitable for a variety of water treatment plants, these grinders ensure pump preservation by preventing long fibers and particles, while improving preconditioning during primary treatment. They offer an alternative to inflow shredders.

Versatility in sludge treatment

Designed specifically for sludge treatment applications, PCM macerators are suitable for both new water treatment plants and retrofits of existing plants. Their usefulness extends to the protection of pumping stations treating raw wastewater, as well as maceration and mixing applications in various industrial sectors such as paper mills or oil production units.

Discover our new PCM industrial pumps and equipment catalogue here.

Benefits

PROCESS SECURITY

- Maintains pump reliability.

- Media preconditioning.

- Replacement of the screens upstream of the station.

- Reduced maintenance costs associated with the use of pumps.

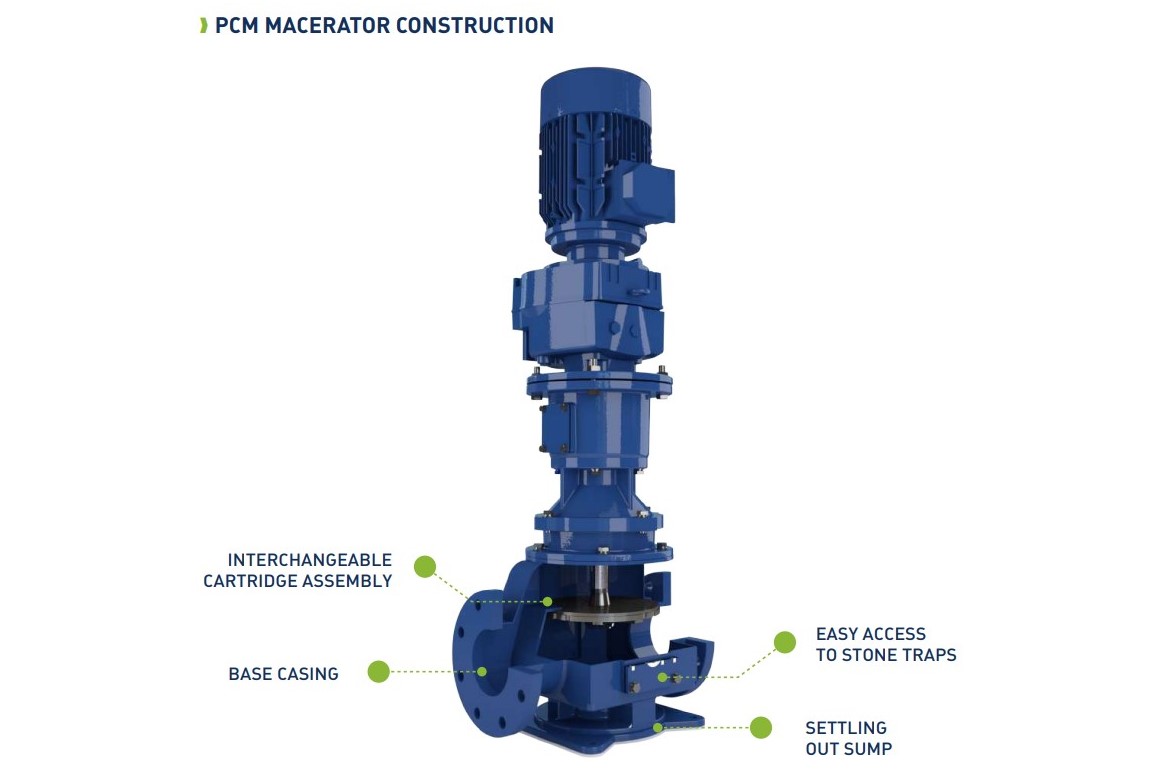

EASY MAINTENANCE

- Few spare parts.

- Interchangeable cartridge assembly.

- Easy and direct access to the side hatches to clean the body.

- Reduced downtime for preventative maintenance.

OPTIMIZED CUTTING PERFORMANCE

- Cutting head and shear plate designed for more efficient cutting.

COMPETITIVE AS FOR ITS LOW OPERATING COSTS

- Low running costs.

- Reduced energy consumption.

- Reduced downtime.

- Downstream Equipment Protection.

Performances

- Maximum flow rate: 400 m3/h

- Fluid concentration: up to 150 g/l