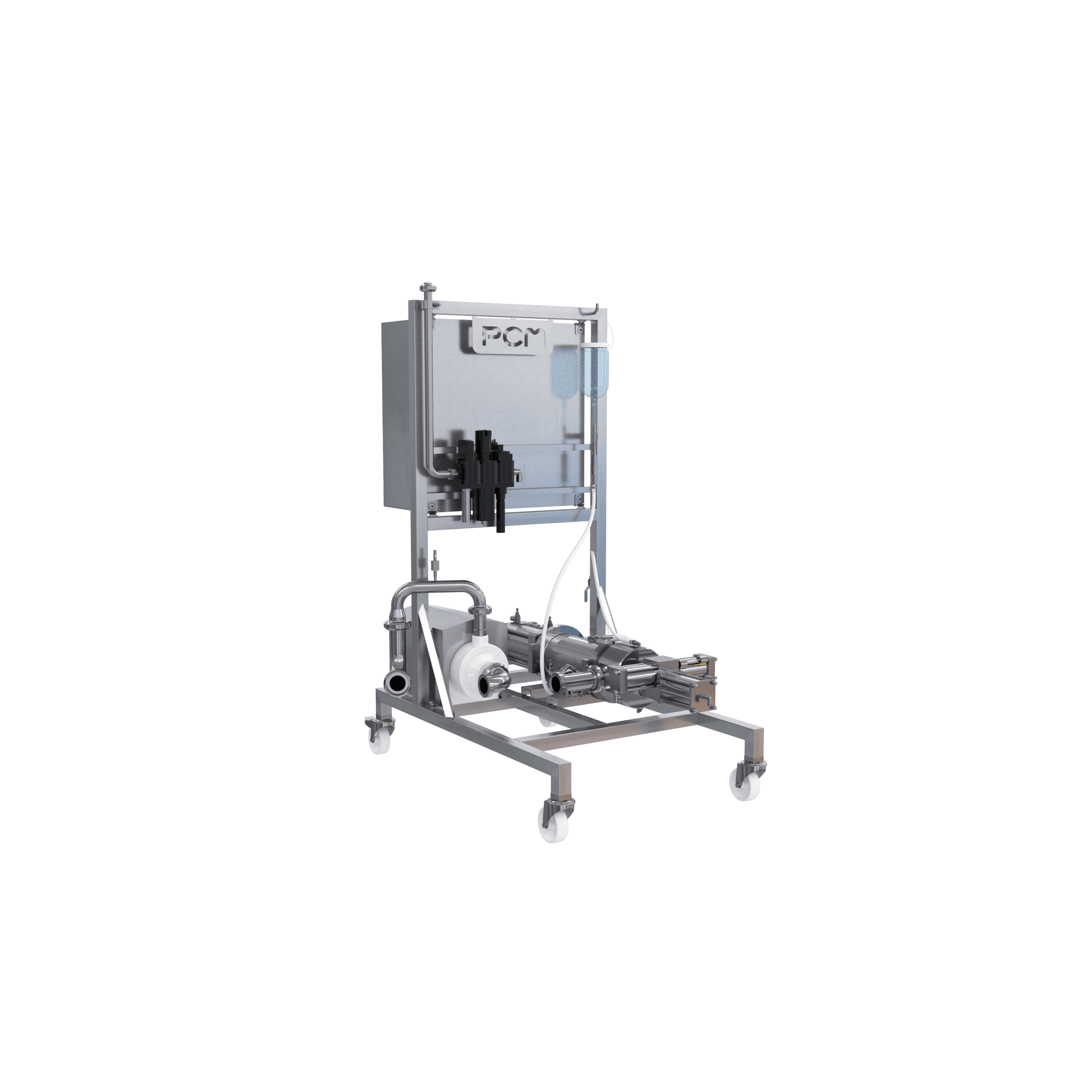

PCM Dosydrum, emptying and dosing food system

The only hygienic solution on the market which is able to unload/transfer viscous fluids with or without particles, and cleanable in place without any dismantling.

PCM Dosydrum also stands out thanks to the Dosys™ technology which offers major advantages versus classic competing solutions.

- Unloading of preparations with delicate solid pieces

- Cleaning In Place (CIP) of the equipment

Its functions are:

- Empty products (stored in drums, European bins, buckets, …)

- Transfer products (to a packing hopper, an intermediate tank, or a stirrer)

- Inject products in line (dilution or mixing processes)

- Dose/Refill products (filling trays, pots, or various toppings)

Applications are multi-market: vegetable preparations, fruit purees or concentrates, various toppings, tomato concentrates, sauces with pieces, cosmetic creams, ...

Discover our new PCM food pumps and systems catalogue here.

Benefits

Unloading/dosage solution, the system includes many advantages:

TRANSFER AND DOSAGE OF VISCOUS PRODUCTS WITH OR WITHOUT PIECES

- Dosys™ technology allows you to have pieces up to 48 mm

HYGIENE

- Cleaning In Place system

- Proven hygienic design on the Food markets

- CE1935-2004 & FDA compliances

MINIMIZING YOUR LOSS OF INGREDIENTS

- The design and body of the Dosys pump™ allows the user to recover all product (no dead volume)

- Complete emptying of the vessels thanks to up and down system

MOBILE, COMPACT, AND EASY TO USE

- Low footprint < 1m²

- Equipped with wheels for mobility around your production floor

- Touch display with built-in automation : simplified management of the operating modes (production/cleaning/ defaults)

- Flexible solution : adaptation to Eurobins, drums, or others vessels

- Increased safety: no moving parts are accessible

BUILDING OF THE SYSTEM

- Dosys™ technology

- DACC feeder with pneumatic actuators

- Suction rod with beveled design to allow passage of particles

- Cleaning in place sleeve for the suction rod

- Built-in CIP centrifugal pump

- Electropneumatic Control Panel

- Stainless steel frame on swivel wheels

- Up and down system by electric cylinder

Options

- Filling nozzles suitable for miscellaneous packaging types

- Scraper Plate equipped with a dedicated Nitrile seal for sticky fluids

- On-request adapting of the scraper plate’s shape: Euro bin, bucket, ...

- Selecting the Dosys™ pump model depending on the fluids (particle sizes, stroke, flowrate...)

Performances

The Dosys™ Pump is the only pump capable of dosing fluids with solid particles with extreme accuracy at high flow rates.

- Respect of solid ingredients (whole way passage up to 48mm)

- High level of precision/repeatability : +/- 0.5 %

- From 18 cc to 2654 cc per dose

- Up to 30 doses/min for 18 cc doses

- Up to 15 doses/min for 2654 cc doses

- 4 bar maximum pressure for doses greater than 636 cc

- Parts in contact with product: Stainless steel 316L

- Seat valve: PTFE

- Gaskets : FKM and silicone

Discharge connections: 1,5’’ to 2.5’’ – SMS/DIN/CLAMP on demand