Food transfer pumps

Protect valuable ingredients: no ingredient is too complex

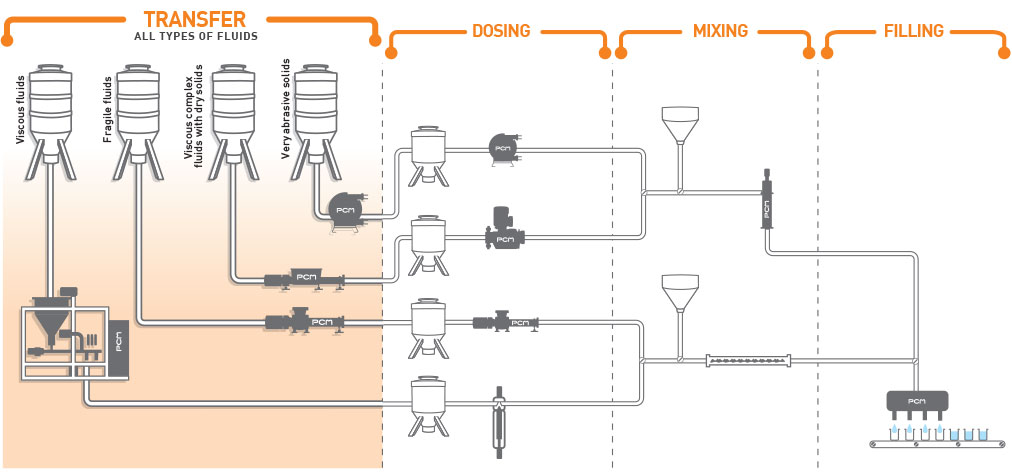

PCM transfer solutions are the best choice for pumping a wide range of ingredients from thin liquid to highly viscous pastes and sauces, at cold and hot temperatures. These ingredients can be sticky, slippery or contain solids (including large chunks and soft pieces such as chopped vegetables and whole fruits).

PCM transfer pumps and systems are also recommended for applications that require pressure variations, depression and viscosity variations.

The choice of the technology will depend on the application and its requirements.

Benefits of PCM progressing cavity pumps for transfer applications

Preserve ingredients and texture with our food transfer pumps

High-value ingredients often have unique qualities and texture. The low-shear, low-pulsation operation of PCM progressing cavity pumps for the food industry enables you to move large quantities without damaging the ingredient’s intrinsic properties. This means you can avoid the high costs typically associated with trying to recreate the proper texture of an ingredient that has been altered.

Reliable performances

PCM’s food transfer solutions use the innovative Moineau PCP technology, allowing for a higher output than other pump technologies typically used in the food industry, whilst also keeping maintenance to a minimum. PCM have extensive experience in meeting the strict cleaning requirements of the food industry and our transfer solutions offer a unique combination of reliability and efficiency, ensuring you’re able to meet the stringent food safety regulations required today.

Other technology for transfer applications

PCM Delasco™ peristaltic pumps

With only one item in contact with the pumped product and low operating speed, peristaltic pumps are ideal for transfer very abrasive and/or corrosive fluids (musts, ground meat juices with bone fragments...). They are also able to transfer soft or solid pieces without any damage (e.g. peach transfer).

Furthermore, they can easily integrate specific industrial processes as occasional dry running is possible without damage occuring.