Aircraft de-icing

Ice accumulation is a serious safety hazard for aircraft. Deicing fluid, a mixture of a chemical called glycol and water, is generally heated and sprayed under pressure to remove ice and snow on the aircraft.

Snow, ice or even frost accumulated on the aircrafts changes their shape, disrupts the airflow across the surface and reduces lift. Because of this potentially severe consequence, de-icing is performed at airports with temperatures dropping dangerously low.

Several French airports have deicing facilities with PCM pumps installed either on cranes (fixed) or on trucks (mobile) for pumping high-grade glycol based de-icing agent. 2 to 6 truck units are necessary for deicing an aircraft depending on its size.

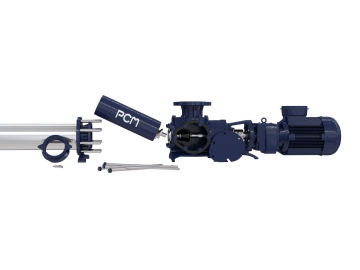

Cast iron PCM EcoMoineau™ M series pumps have been chosen for these deicing modules for their constant continuous flow rate ability allowing the glycol and water mixture to circulate in a stable way, without pulsation. Furthermore, these robust pumps gently convey the fragile glycol agent without shearing at speed rotation below 250rpm, preserving the agent deicing properties in the most efficient way.

Context

CUSTOMER

- Roissy Airport, Paris (France)

- Lyon-Saint Exupéry Airport, Lyon (France)

- Blagnac Airport, Toulouse (France)

CHALLENGE

- Minimize waste of expensive high-grade glycol product

- Fragile product must not be altered in order to keep de-icing properties.

BENEFITS

- PCP technology protects and maintains the low shear of high-grade glycol

- At this speed, the structure of the agent is preserved as well as its de-icing properties

- Integrated/Monobloc construction, shortest and lightest design easy to integrate into cranes or trucks.

- Seal can be changed from drive site by simply disconnecting the drive.

- Shaft line (rotor, coupling rod, driving shaft) can be removed in one piece : easy maintenance, reduced downtime.