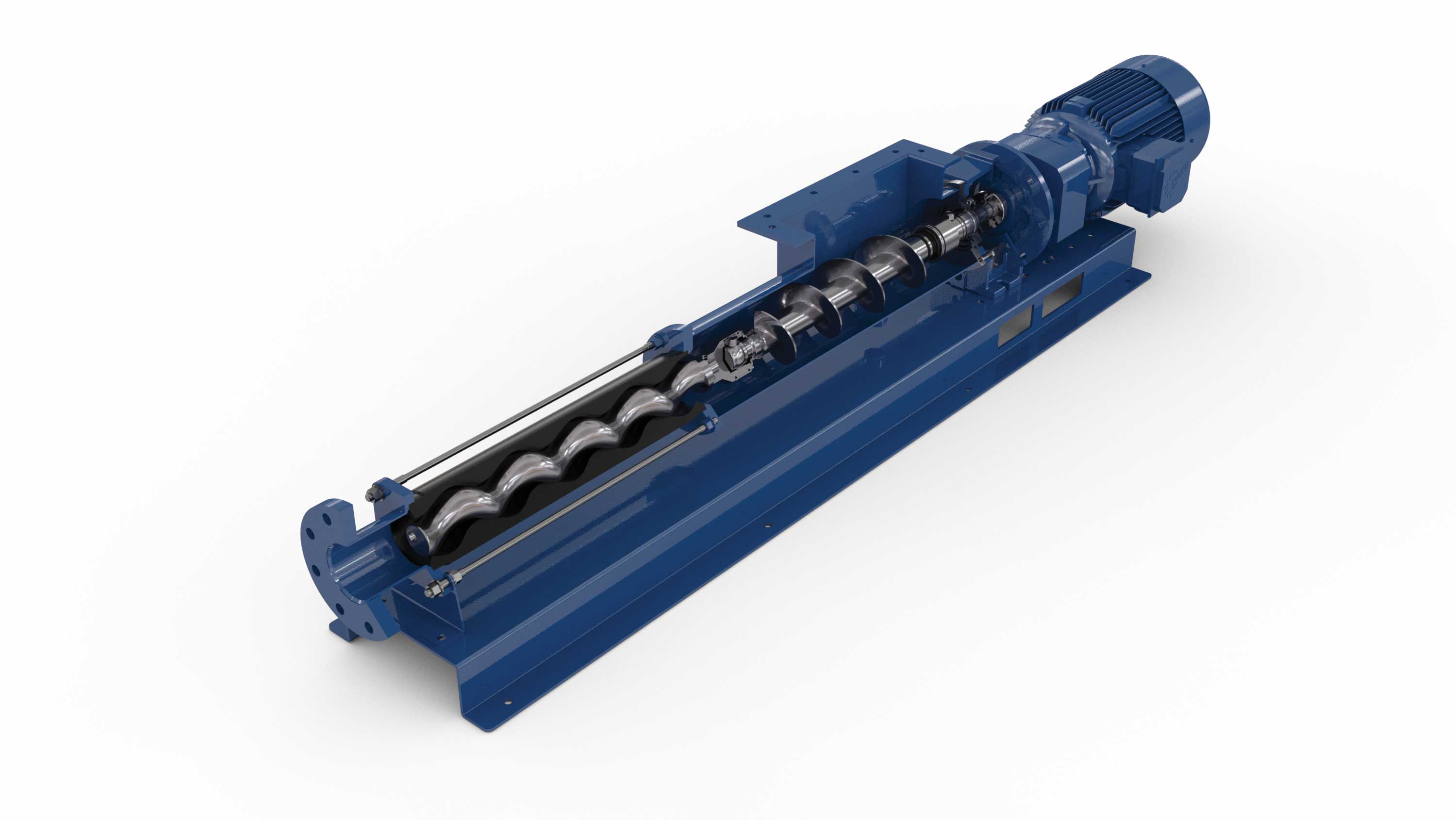

PCM Hopper Progressive Cavity Pumps MSH Series (Force feeding pumps)

Transfer of Complex Fluids

Using Moineau™ technology, PCM MSH Progressive Cavity Pumps are designed for the transfer of complex fluids used in a wide range of industrial applications.

Viscous, pasty, sticky, high-solids, or solid-containing fluids are common in many applications. They represent harsh conditions requiring the use of well-adapted pumps.

Robust design for increased productivity and profitability

Simple but robust in design, and thanks to the use of PCM hydraulics, the range of PCM MSH force feeding pumps allows you to combine consistent productivity and profitability even with complex fluids.

Adjust the use of the pump thanks to its adaptable Archimedean screw.

The PCM MSH range of progressive cavity pumps is suitable for many industrial applications thanks to a modular design of its Archimedean screw. Depending on the product being pumped, you will have the choice of using the closed or open Archimedean screw.

Also effective in transferring high-viscosity, non-sticky fluids.

The PCM MSH series of force feeding pumps is particularly effective for the transfer of non-sticky fluids with high viscosity or low flow capacity and requiring manual or gravity feeding.

Discover our PCM industrial pumps and equipment catalogue here.

Advantages of PCM MSH hopper pumps

- Respect for the pumped product

- Constant, pulsation-free flow

- Flow rate proportional to speed

- Easy maintenance

- Valveless operation

- Hopper coupled with an Archimedean screw for manual or gravity feeding of highly viscous or low flow fluids

- Spare parts common with other Moineau™ ranges

- Constant, pulsation-free flow

Adaptable construction of PCM MSH hopper pumps

- Open Archimedean screw: perfectly meeting the transfer constraints of sticky products, it allows the fluid to circulate between its core and its perforated coils, thus avoiding any risk of compaction. The Archimedean screw with open coils is the best solution to the risk of possible overflow of the hoppers.

- Closed Archimedean screw: specially designed for non-sticky viscous products, it offers a very high conveying efficiency thanks to the optimized surface of its turns. The Archimedean screw with closed coils guarantees optimal force feeding of the sludge.

Performance of PCM MSH hopper pumps

- Flow rate: from 0.04 to 70 m3/h

- Pression : 24 bar

- Viscosity: up to 40,000 cPo

- Maximum solids content: 20%