Stuffing system - PCM Dosyfeed and Additivefeed

PCM Dosyfeed system allows viscous and heterogeneous ingredients stuffing such as jam, honey, chocolate in small buns.

PCM Additivefeed system will be more adapted for homogeneous liquid aromas stuffing in various baked preparations.

Let's discover the new catalogue.

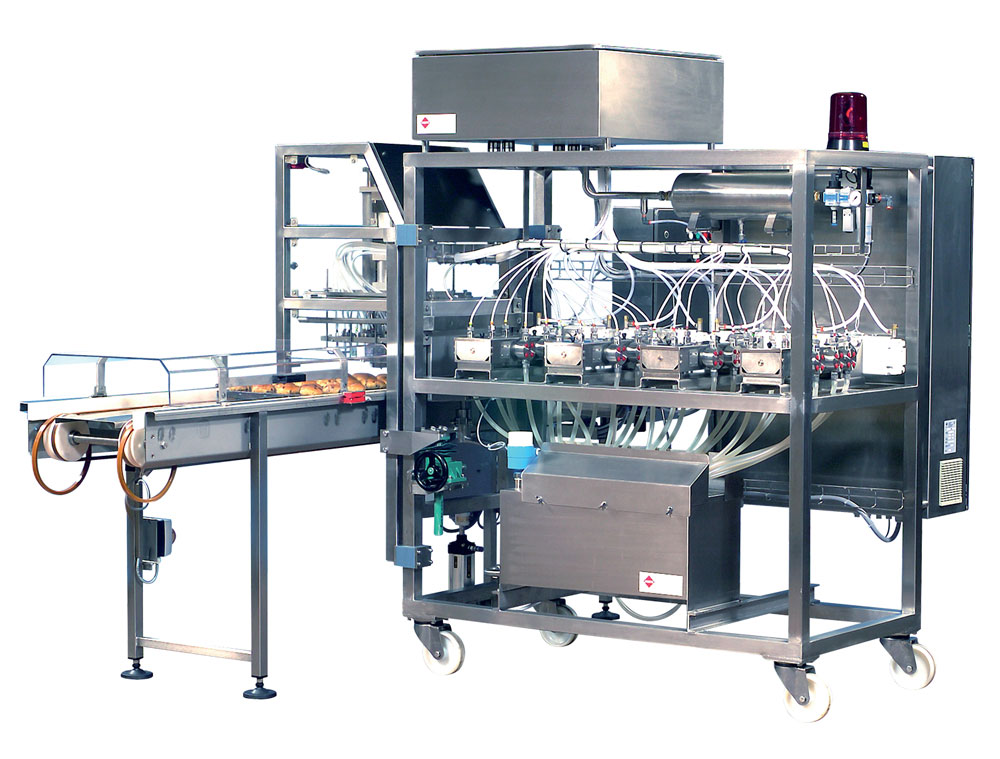

PCM Multi-injection station (p.72)

Systems benefits

A "CUSTOMIZED" SOLUTION

- Can be adapted to the dimensions of your final products and to the distribution of stuffing ingredients

- PCM Dosys™ or diaphragm MDS (Synchronized Multi Dosing heads) technology meeting the customers requirements (product, cadence, doses...) and a needle system adapted to viscous, stringy, heterogeneous stuffing products...

- Consideration of existing installations, machine dimensions, conveyor widths

100% RELIABLE & REPEATABLE

- Dosys™ technology (see page 7)

- MDS technology (see page 9)

HYGIENIC

- Hygienic design of components

- Cleaning in place of the overall system

Example of realization

PCM DOSYFEED 22 HEADS - Small milk rolls stuffing with viscous products

Process

- Doses: 3 gr/rolls [0.007 lbs] - machine cadence: 24 000 products/h

- Container unloading and transfer of the product to a buffer tank

- Container changeovers without production shutdown

- Product temperature retention throughout the process

- Stuffing of 22 rolls simultaneously

- Synchronization of the stitching with the conveyor

- Rolls detection to avoid the dosing in the absence of products on the conveyor

- Cleaning in place of the overall installation

Construction

- 1 Dosys™ technology GACC pump for the containers unloading

- 2 dosing units including 11 Dosys™ technology pumps with common Brushless actuator

- 2 nozzle distribution plates for 2 x 11 rolls simultaneous stuffing

- 22 suck back nozzles including for each 11 needles for the stuffing distribution

- 3-axis manipulator to handle the needle plate

- Double jacketed collector and process piping for temperature retention

- Optical sensor for rolls detection

- 2 Cip tanks for nozzle distribution plate cleaning and CIP return tank

- 1 utility package for CIP, air, hot water / 1 centrifugal pump for CIP return

- Sensor for product presence, temperature, level and pressure

System performances

(depending on the DOSYSTM pump used)

- Pressure: 5 bars max

- Speed: 60 strokes/max (if pump set at its maximum volume capacity)

- Accuracy - Repeatability: +/- 0,5%

- Speed up to 21 000 buns/hours

- Particle sizes: 48 mm max